Key feature :

The patented Tri-Laser System provides accurate, reliable and repeatable particle size analysis for a various range of applications by using the proven theory of Mie compensation for spherical particles and the proprietary principle of Modified Mie calculations for non-spherical particles.

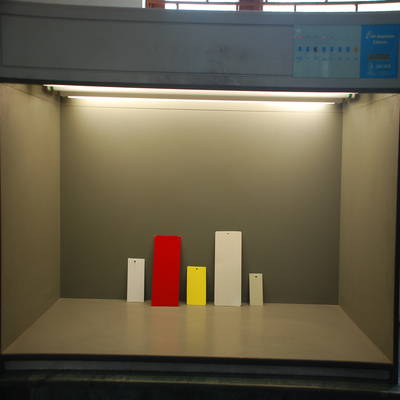

Key feature : It provides D-65 light to match shade under standard setup conditions. Other set of lights are also available to match shades under different lights like TL84 etc.

Key feature : This instruments duplicate how our eyes see colour. The instrument measures the product colour and give numerical values (L*a*b) that correlate to what you see. These objective measurements optimize the confidence of our quality decisions.

Key feature : High precision instrument to measure tri angle gloss with recording, USB & Bluetooth data transfer.

Key feature : Handy, universally applicable coating thickness gauge with integrated probes, cable probes and interchangeable internal and external probes.

Key feature : To check the impact resistance of coating on direct impact. This ensures the mechanical toughness of coating to sudden impact.

Key feature : To check the hardness H-4H for scratch resistance.

Key feature : To check resistance of coating underweight for scratch resistance.

Key feature : Accurate and reliable testing of adhesion, hardness, the porosity of coatings of paints in metal sheets, strips.

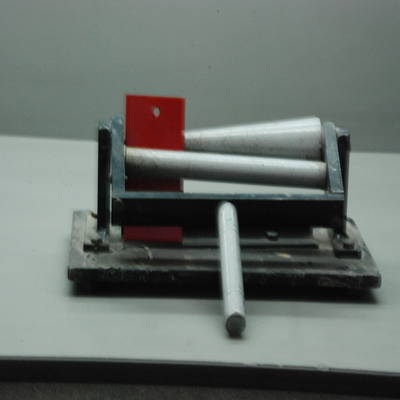

Key feature : Conical Mandrel is a laboratory apparatus to bend coated test panels over a conical shaped mandrel in order to assess the elasticity or resistance of a coating paint to cracking; elongation at different radius (3 mm to 37.5 mm) and / or detachment from a metal test panel.