The basic principle of the process is propulsion of electrostatically charged powder which travels through gap between spraying gun and earthed metal work piece with combined action of compressed air and electric-field carrying charged ion directing the charged powder onto the surface of metal workpiece.

The charged powder adheres to the surface of earthed metal work piece and then placed into oven where it melts. Then metal is subjected to cooling to leave a high quality coating.

The Particle size is chosen strictly in ranges between 150-200µm.

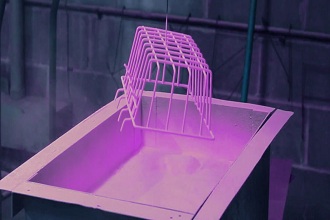

This process requires a powder container with an air pressure regulator.

The compressed air is dispersed uniformly throughout the container with the help of porous membrane at the bottom of container to make the plastic powder bubble-up like liquid.

This fluidized bed of plastic powder when comes into contact with pre-heated metal work piece the powder near the province adhere to its surface and melt down. The metal is then lifted up to cool to give a high quality coating.

Both Finer and coarser particles are applicable for this process.

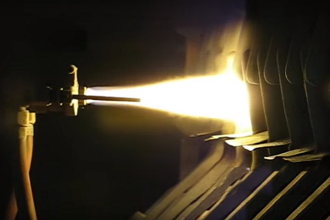

Powder coating is fluidized by a compressed air and fed into the flame gun. The powder is then injected at high velocity through a flame of propane. The residence time of the powder in the flame and its vicinity is short but just enough to allow complete melting of the powder particles. The molten particles in the form of high viscous droplets deposit on the substrate forming a high-build film upon solidification.

The objects which cannot be subjected to heating or the objects which are not going to fit inside an industrial oven are coated with this technique. Large articles are generally preferred.

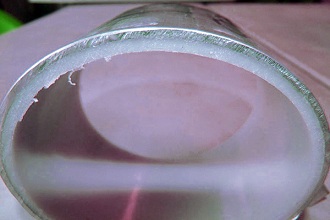

The object to be coated is heated at desired temperature along with spun and tumbled at constant speed. Powder is then injected into the cylinder through spray gun. The simultaneous spinning and tumbling gives consistent coating inside the object.

The powder in excess exhales outside the object providing uniform coating inside the object upon cooling.

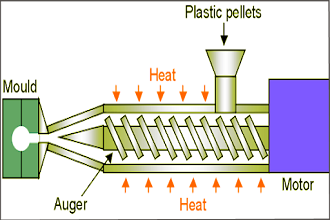

A continuous strand of wire travel across the molten powder exuding from die of heated extruder barrel gives the uniform surface coverage to wire which upon cooling provides the high quality coating.

Coating procedure is applicable to any particle size.